Service Factors

Service factor FS is a coefficient that enables to take into consideration real operating conditions of the gearbox. In order to make a correct selection, the service factor of the gearbox must be higher than the one required for the application.

Table below gives indications for the right selection having determined the classification of the uniformity of operation.

A) Uniform operation

Light screw conveyors, fans, assembly belts, light conveyor belts, small agitators, elevators, cleaning machines, filling machines, testing machines and belt conveyors.

B) Moderate shocks, non-uniform operation

Decoilers, feed drives for wood processing machines, hoists, balancing machines, tapping units, heavy conveyor, belts, winches, sliding doors, stall dunging machines, packaging machines, cement mixers, crane traveling mechanisms, mills, bending machines and gear pumps.

C) Heavy shocks, extreme non-uniform operation

Stirrers and mixers, shears, presses, centrifuges, rolling stands, heavy winches and lifts, grinding mills, stone crushers, bucket elevators, punching machines, hammer mills, eccentric presses, folding machines, roller tables, tumbling barrels, choppers, shredders, vibrators.

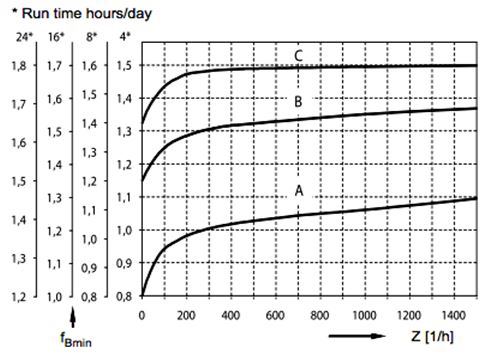

Service Factor Consideration of stop-start frequencyCorrection factor fs have to be applied for Gear Boxes operating with more than 10 starts per hour.

| Starts / Operating Hour | 10 | 11~200 | above 200 |

|---|---|---|---|

| Correction factor fs | 1 | 1.1 | 1.4 |