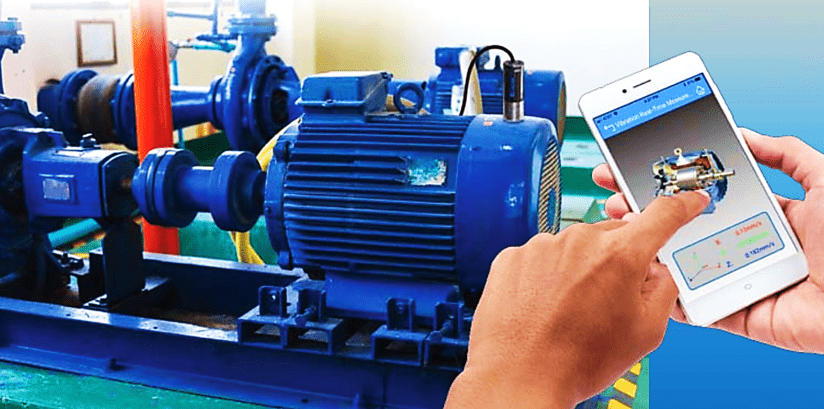

The Pro-3200 vibration analyzer integrates three operations: vibration measurement, analysis and diagnosis all into one operation; moreover, the diagnosis is operated interactively, in real time.

The portable case contains an IoT (Internet of Things) gateway, smart vibration sensors and a rechargeable mobile power pack with a 12 hour battery pack. This allows technicians to carry the device onsite for measurement diagnosis operations.

With built-in Wi-Fi, it is accessible simultaneously by up to 20 mobile devices via a free mobile app for iOS and Android.

The vibration sensors can be easily located in the correct ISO-10816 positions for data collection on rotating machines to perform an analysis of live data in real time. And this device can be used on any rotating equipment (motors, pumps, air compressors or gear reducers). The Pro-3200 interactively integrates measurement, analysis, and diagnosis all in one device.

IMPORTANT FEATURES

-

Time-Frequency Selectable –

The gateway provides both time-domain and frequency-domain vibration signals that are selectable via smart phones.

-

Replaces Typical Frequency Analyzers –

Working together, the smart vibration sensors, IoT Gateway and smart phones represent a replacement of expensive and complicated Frequency Analyzers virtually anywhere, any time.

-

All-in-One –

The Pro-3200 integrates three operations: vibration measurement, analysis and diagnosis all into one operation; moreover, the diagnosis is operated interactively, in real time.

-

Plug-and-Play –

All operations are powered by a mobile power pack and the diagnosis is delivered via wireless Wi-Fi connections. No power cords or network wires are needed, just plug and play: amazingly easy to use.

Onsite Instrument Use

-

Measures 3-axis RMS values and compares against the motor vibration specifications.

-

Examines the FFT data so that the vibration energy distributions on frequency domains can be reviewed and diagnosed for the four possible defects: bearing defects, misalignment, unbalance and soft foot, which are 90% of a motor’s mechanical failures.

-

IoT and Smart Phones can work together on an interactive diagnosis.

-

Record all measured data and diagnosis results for future motor health reference.

Key Application – Operational Data Collection on machines 1st commission.

-

The portable instrument can help the installer collect all operational data on machines’ 1st commission, a vital information for future maintenance reference, as well as for Big Data analysis.

-

As the use of Big Data Analysis technology trending up strongly, the operation data collection on 1st commission would become a popular practice of main-stream motor manufactures, and the portable vibration diagnosis instruments would be indispensable for all installers or maintenance personnel of dealers, makers, factory, institutes, hotels, hospitals, schools, warehouses,…etc.

Download Brochure & Installation Guide:

TECOM Pro-3200 Portable Vibration Analyzer & Diagnosis Instrument.pdf

TECOM Pro-3200 PVDI Installation Guide & Measurement-Procedures.pdf

You Tube Links:

Pro-3200 PDVI Introduction by TECO Westinghouse

Pro-3200 PDVI Demo by TECO Westinghouse